3 Core Coiled Spiral Cable Description:

3 core spiral cable with 3 x 1.0mm² PVC insulated cores sheathed in black polyurethane. Ideal for non-permanent connections as it eliminates the trip hazard of trailing cables and is compact for easy storage.

3 Core Coiled Spiral Cable Advantages:

1, Good heat resistance, good crusts performance, mechanical and electrical properties.

2, Standard: RoHS, REACH compliance

3, The spiral cable Jacketing is suitable for a broad range of medical applications.

4, Fluoropolymer silicone composite tubing provides multimodality sterilization capability and higher lubricity, lighter weight, and added strength. CIT wire cable jacketing material.

3 Core Coiled Spiral Cable Information

| Conductor | Bare copper conductor, to DIN VDE 0295 cl.5, fine wire,BS 6360 cl.5, IEC 60228 cl.5 |

| Core | Muilt-core |

| Temp | -40°C +90°C |

| Insulation | TPE |

| Sheath | Rubber |

| Sheath colour | Black/white/Yellow/Orange |

| Test voltage | 500V |

| Nominal voltage | 2000V |

| Packaging | Meter marking |

3 Core Coiled Spiral Cable Spec:

| Cross-section mm² |

Spiral length unexpanded (WL in mm) |

Cable Ø app. mm | Spiral-outer Ø app. mm |

Cop.weight kg / 1000 pcs. |

AWG-No. |

| 3 G 0,75 | 500 | 7,1 | 25,2 | 116,7 | 18 |

| 3 G 0,75 | 1000 | 7,1 | 25,2 | 224,7 | 18 |

| 3 G 0,75 | 1400 | 7,1 | 25,2 | 311,1 | 18 |

| 3 G 0,75 | 2000 | 7,1 | 25,2 | 440,6 | 18 |

| 3 G 0,75 | 3000 | 7,1 | 25,2 | 656,6 | 18 |

| 3 G 1,0 | 500 | 7,2 | 26,4 | 156,6 | 17 |

| 3 G 1,0 | 1000 | 7,2 | 26,4 | 301,6 | 17 |

| 3 G 1,0 | 1400 | 7,2 | 26,4 | 417,6 | 17 |

| 3 G 1,0 | 2000 | 7,2 | 26,4 | 591,6 | 17 |

| 3 G 1,0 | 3000 | 7,2 | 26,4 | 881,6 | 17 |

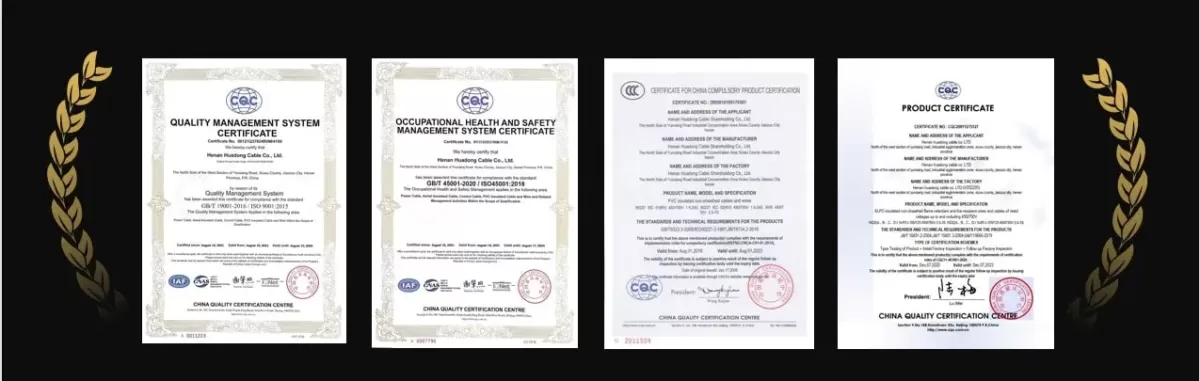

Spiral Cable Why Choose HuaDong Cable

Our Certification

Our Customers

Any Spiral Cable need please contact us. We will contact you within 12 hours.